What Is Bevel Cut And What Are Its Uses?

Share it

The bevel cut is a common confusion for beginners. What is the bevel cut and why is it so important? You are missing out on the benefits and uses of this cut if you have never done it before.

We have created this guide to help you understand the basics of bevel cuts.

A bevel cut is a cut that has sharp edges and is not perpendicular with the top of the material or wood. This is a cut made in a beveled curvature, which has a circular profile and radius. An angle is often measured against a square-edged cut.

To show the sharp edges of the piece, the blade is placed at an angle to the vertical plane. You can also call the bevel cut slope, slope, cant, angled, or slant.

There are several types of bevel cuts, such as A, V and X.

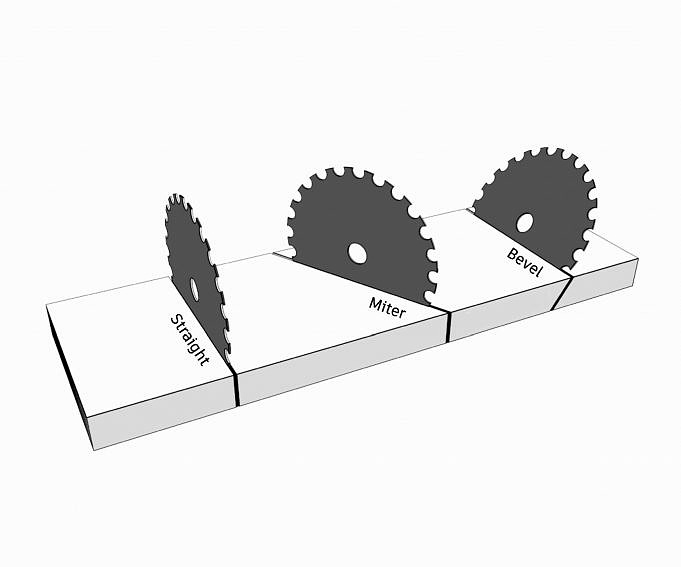

Many people confuse miter cuts and double bevel cuts when they refer to bevel cut. However, these two are very distinct. We’ll get to the difference in a moment.

Bevel cuts are generally used in carpentry to make small, more attractive pieces of wood that are weather-resistant and more pleasing to the eye. Bevel cuts can also be used to soften the edges of wood.

A bevel-cut wood piece can be used as trim around a wall’s base. This will prevent injury and give the wall a decorative look.

Bevel cuts can also conceal the joint between different wood pieces. By attaching the pieces together with an edge that creates a complementary angle, they can be joined. The pieces are then slightly overlapped, creating the illusion of one piece of wood joined together by a bevel cutter.

Most people confuse a bevel and a miter cut, as mentioned above. A miter cut can be any cut made at an angle other than 90 degrees. It also depends on the length and width. Miter cuts give wood a different shape than a square.

The bevel cut is not a 90 degree angle. It cuts wood at an angle other than 90 degrees. This is a cut that is angled relative to material’s face and, most often, not a straight edge.

The best woodworking vises we have listed are ideal for precise and accurate cuts.

Carpentry: Unique Bevel Cut Applications To Get The Perfect Cut On Wood Pieces

- The bevel cutter is used in many areas, including welding, carpentry, and crafting.

- The materials used in crafting and welding are usually made from softwood. For aesthetics and safety reasons, they have a softer edge. It is also easier to join pieces of wood and create geometrical shapes with this softer material.

- To prevent injury from sharp edges, bevel-cut wood materials are used to trim the base of the wall.

- Walls with wood pieces can also be visually pleasing. It is effective in concealing the edges of two pieces that have been fastened together using a complementary angle.

- Two different pieces of wood can be slightly overlapped by using bevel cuts. This technique would make the two pieces appear as one piece of wood.

- Bevel cuts are used for welding to give the joints additional support to withstand heavy loads.

Conclusion

It is usually difficult to make bevel cuts with precision using hand tools. Instead, they are often made using power tools. Some saw gauges don’t give the perfect bevel cut. However, you can use a protractor for checking the blade angle.

To avoid any kickbacks, make sure the fence is set so that the blade faces away from the fence. This will ensure safety. You can also use the miter cut to do this. Anyone can learn to make perfect bevel cuts with a little practice.

You can practice the bevel cut by looking at our top woodworking projects.